What Are truss stands?

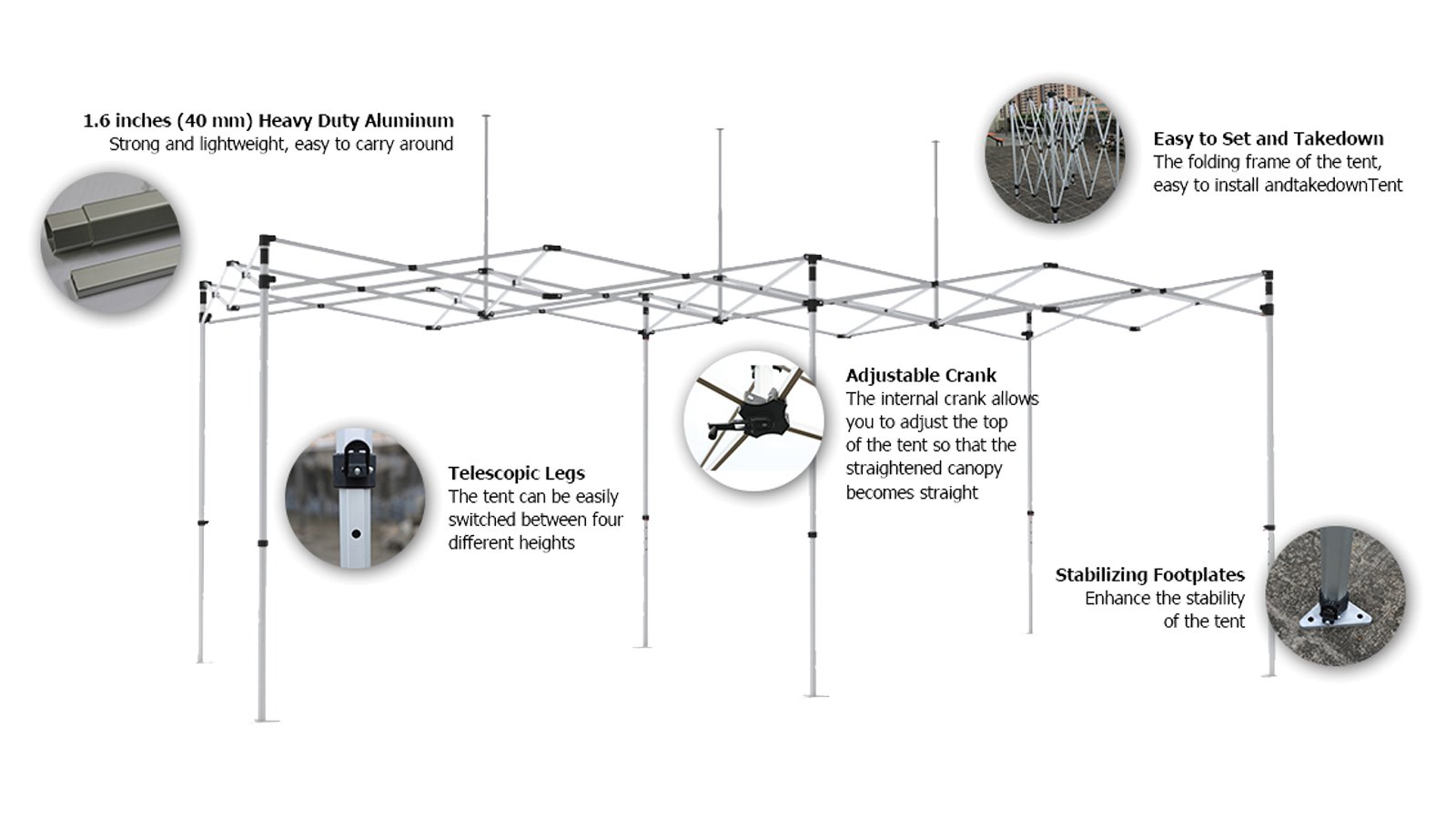

Truss stands are versatile structures that are used in various industries such as event management, construction, and retail. They are typically made of aluminum or steel and consist of interlocking beams that form a rigid framework. Truss stands provide stability and support for various applications, including lighting fixtures, audio equipment, banners, and signage.

The Benefits of Using Truss Stands

Truss stands offer several advantages, making them a popular choice for many professionals. One of the key benefits is their versatility. These stands can be easily customized and configured to suit specific needs and requirements. Additionally, truss stands are lightweight and portable, making them easy to transport and set up at different locations.

Another advantage of truss stands is their durability. Made from high-quality materials, such as aluminum alloys, they are resistant to corrosion and can withstand heavy loads. This makes them ideal for use in outdoor events or construction sites where stability and durability are crucial.

Applications of Truss Stands

Truss stands have a wide range of applications across various industries. Let's explore some of the common uses:

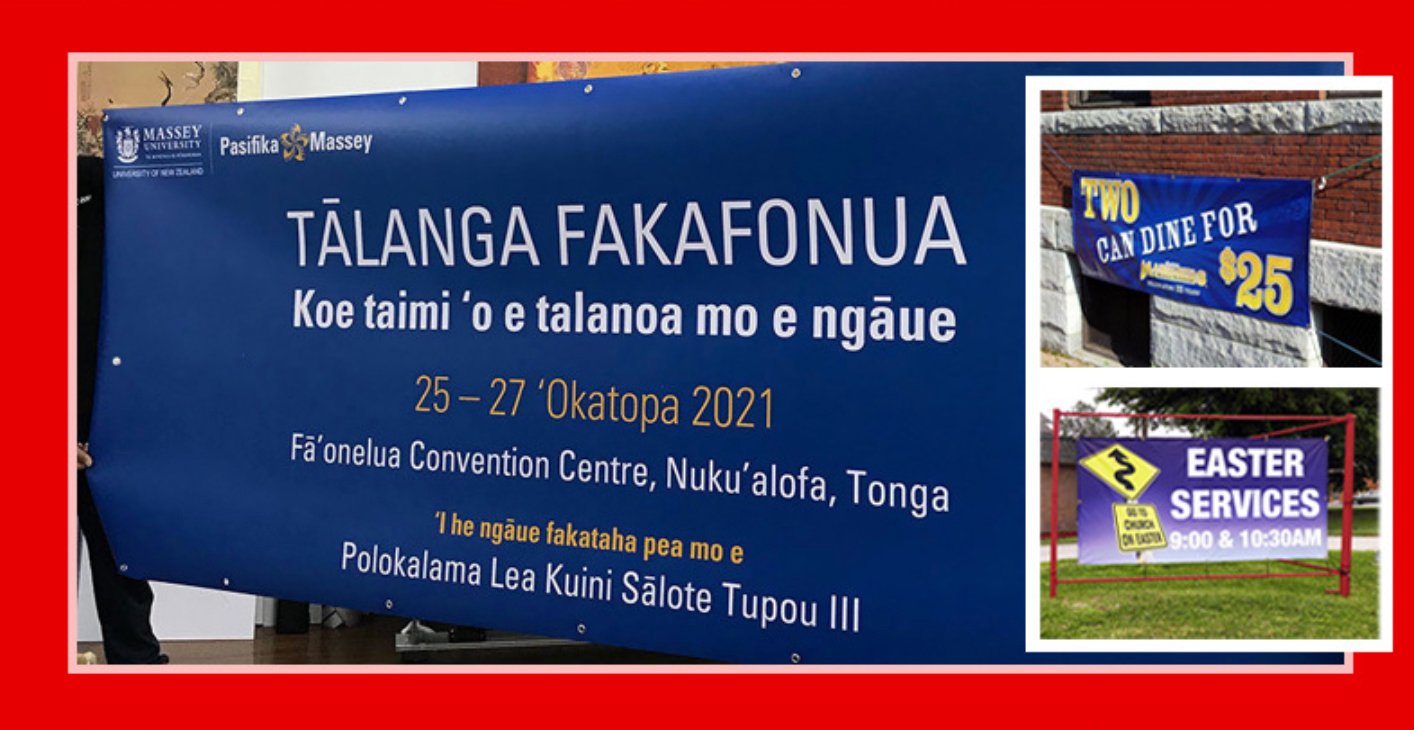

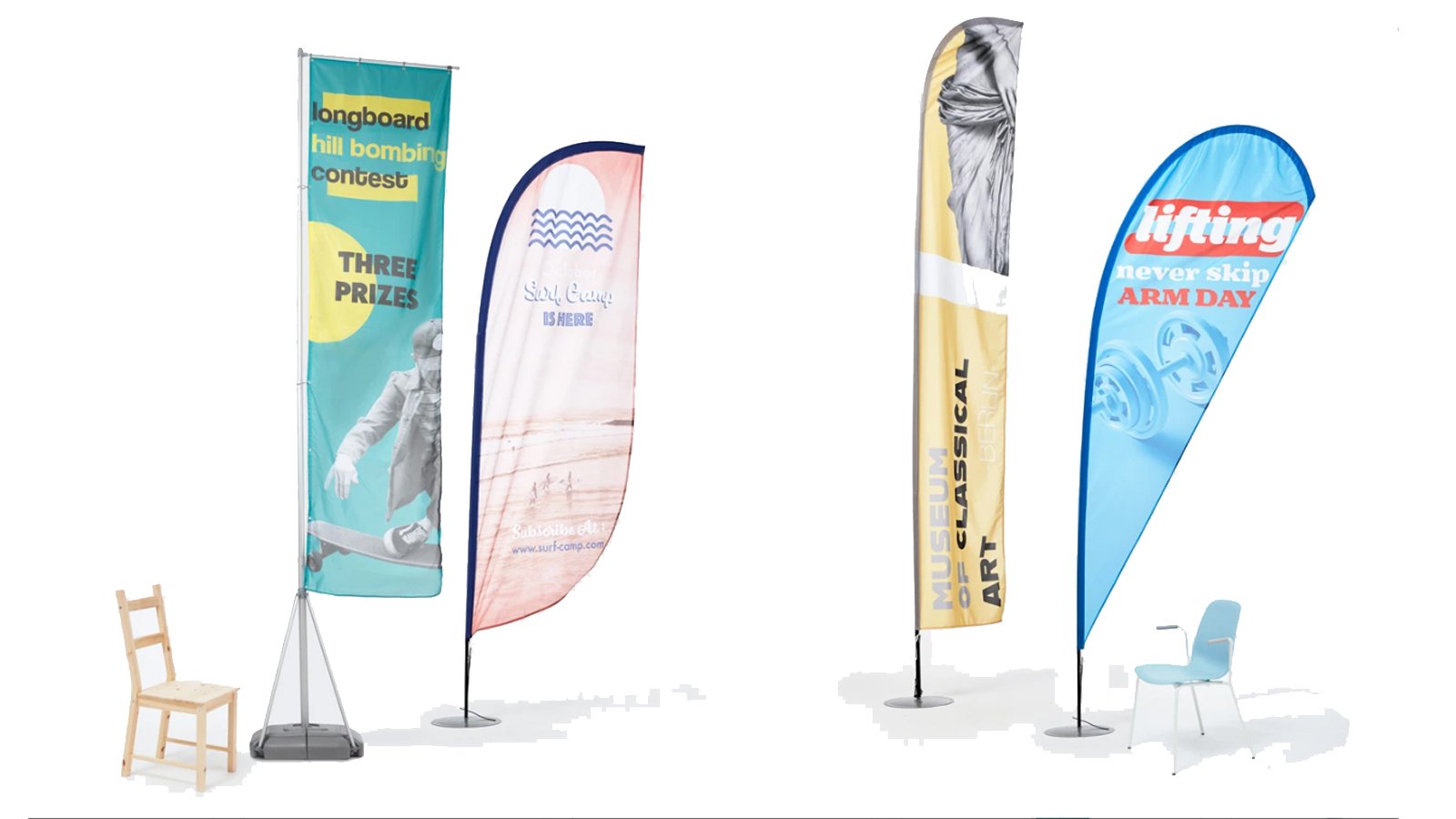

1. Events and Trade Shows

In the event management industry, truss stands are extensively used to create eye-catching displays and structures. They provide a sturdy framework for hanging lighting fixtures, audio equipment, and banners. Truss stands can be easily customized to match the theme and branding of the event, making them an essential tool for creating memorable experiences.

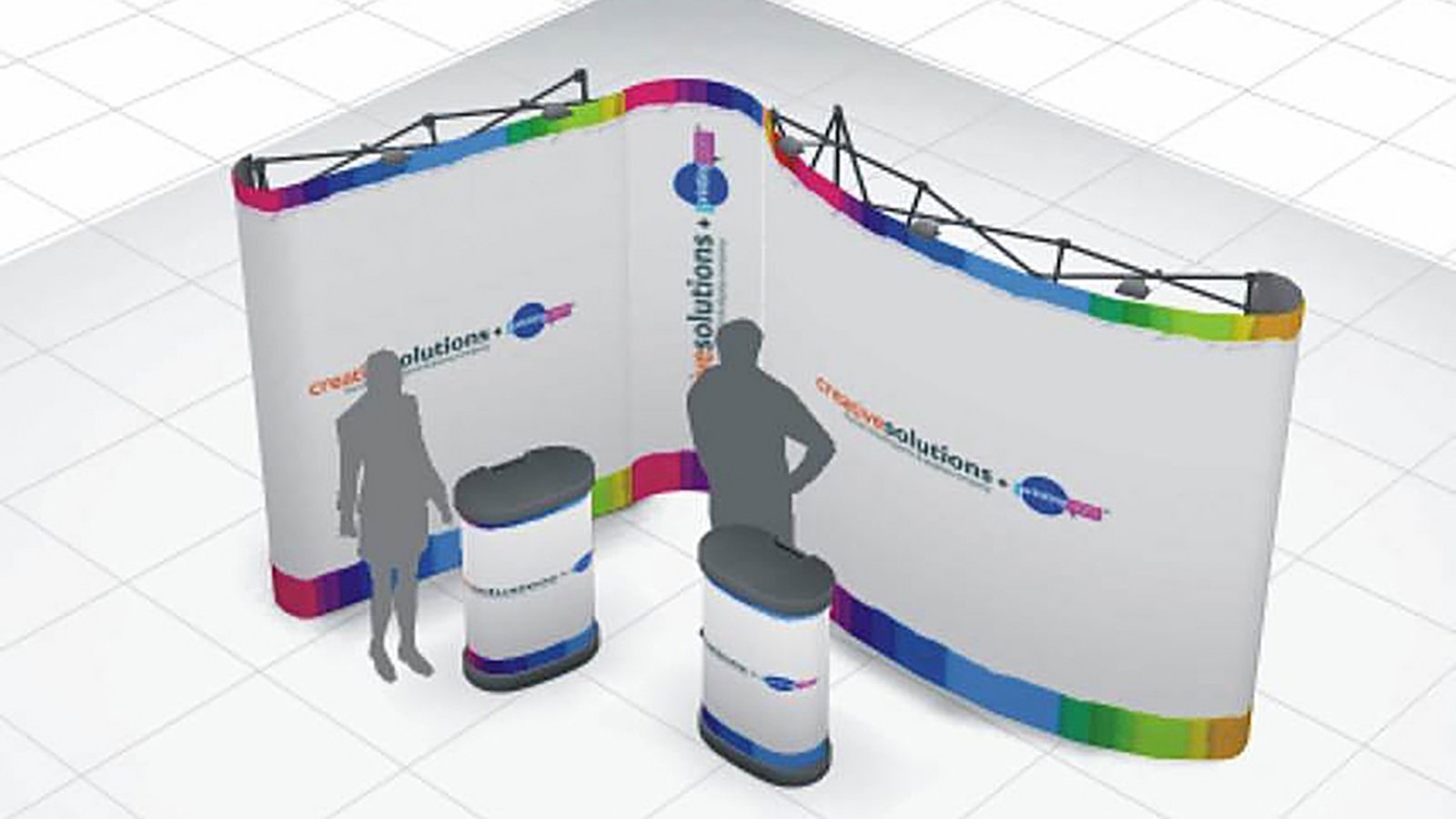

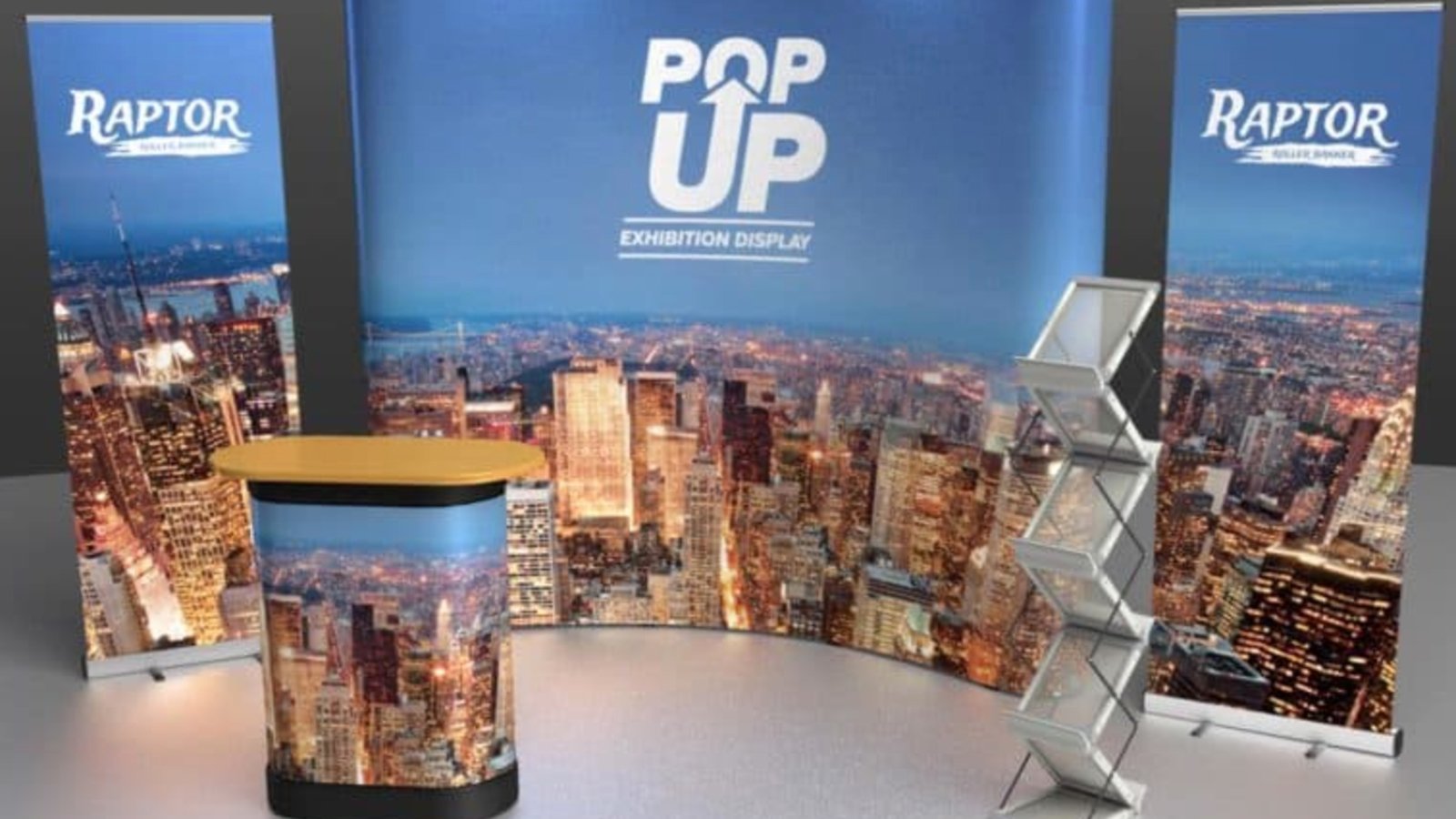

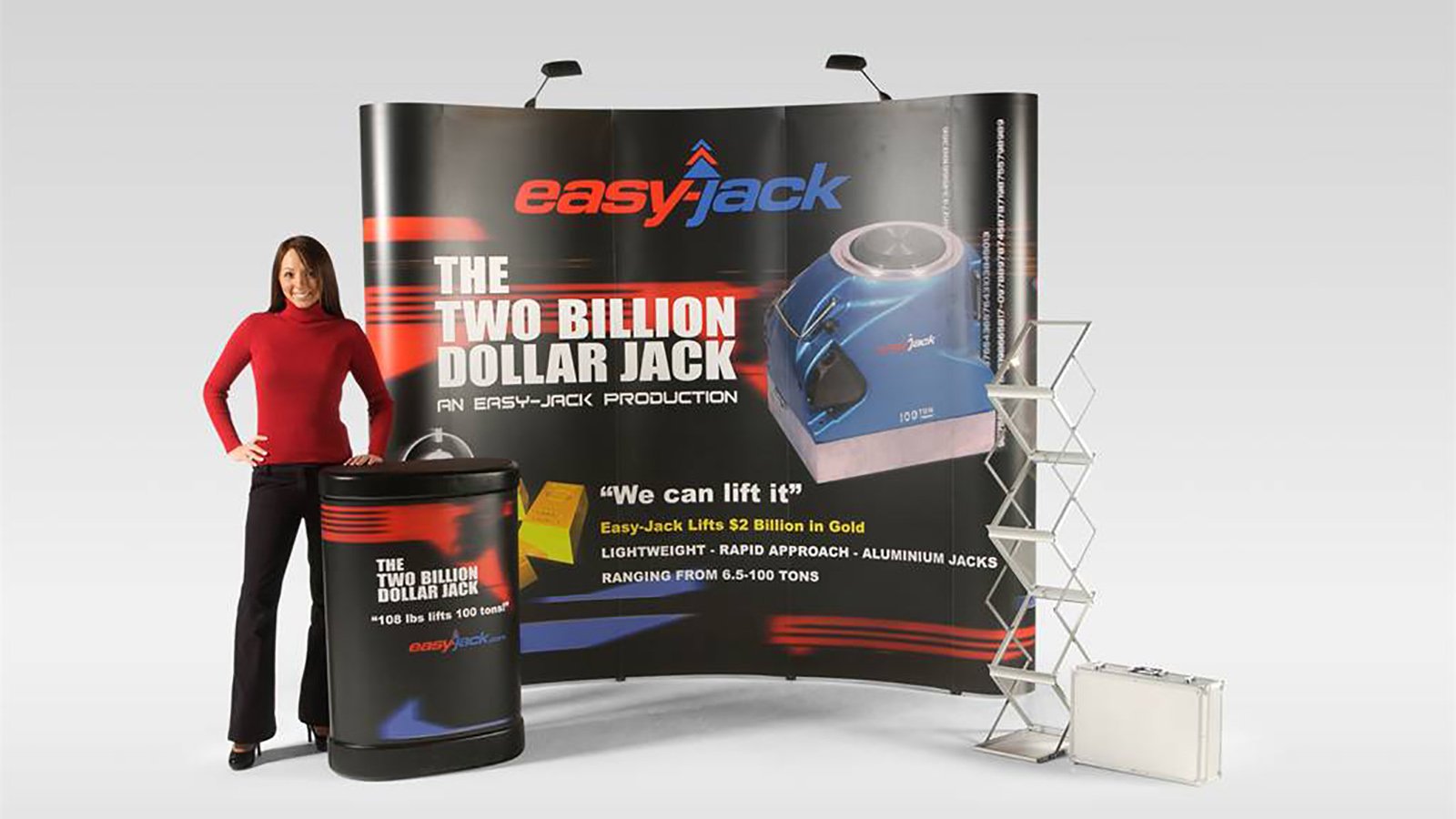

2. Retail and Exhibitions

Truss stands are also widely used in retail settings and exhibitions. They serve as a versatile solution for showcasing products, creating interactive displays, and highlighting promotional offers. The modular nature of truss stands allows retailers to easily adapt and reconfigure the displays based on changing requirements or seasonal campaigns.

3. Stage and Concert Productions

In the entertainment industry, truss stands play a vital role in stage and concert productions. They provide a safe and reliable structure for suspending lighting rigs, speakers, video screens, and special effects equipment. Truss stands are designed to handle the heavy loads associated with live performances, ensuring the safety of performers and audience members.

Choosing the Right Truss Stand

When selecting a truss stand for your specific needs, there are a few factors to consider:

1. Weight Capacity

It is essential to determine the weight capacity required for your intended application. Truss stands come in various load-bearing capacities, so ensure that you choose one that can safely support your equipment or display.

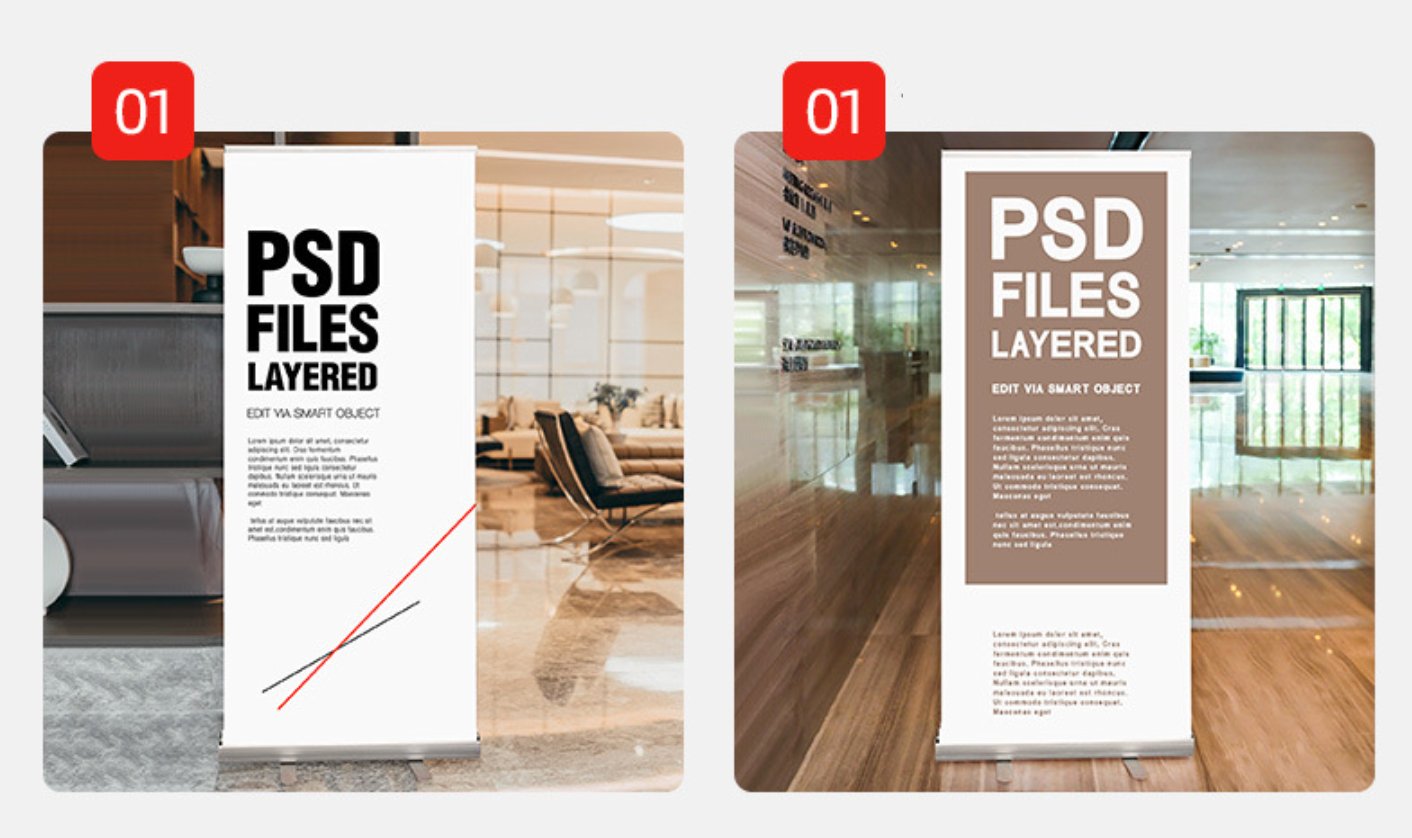

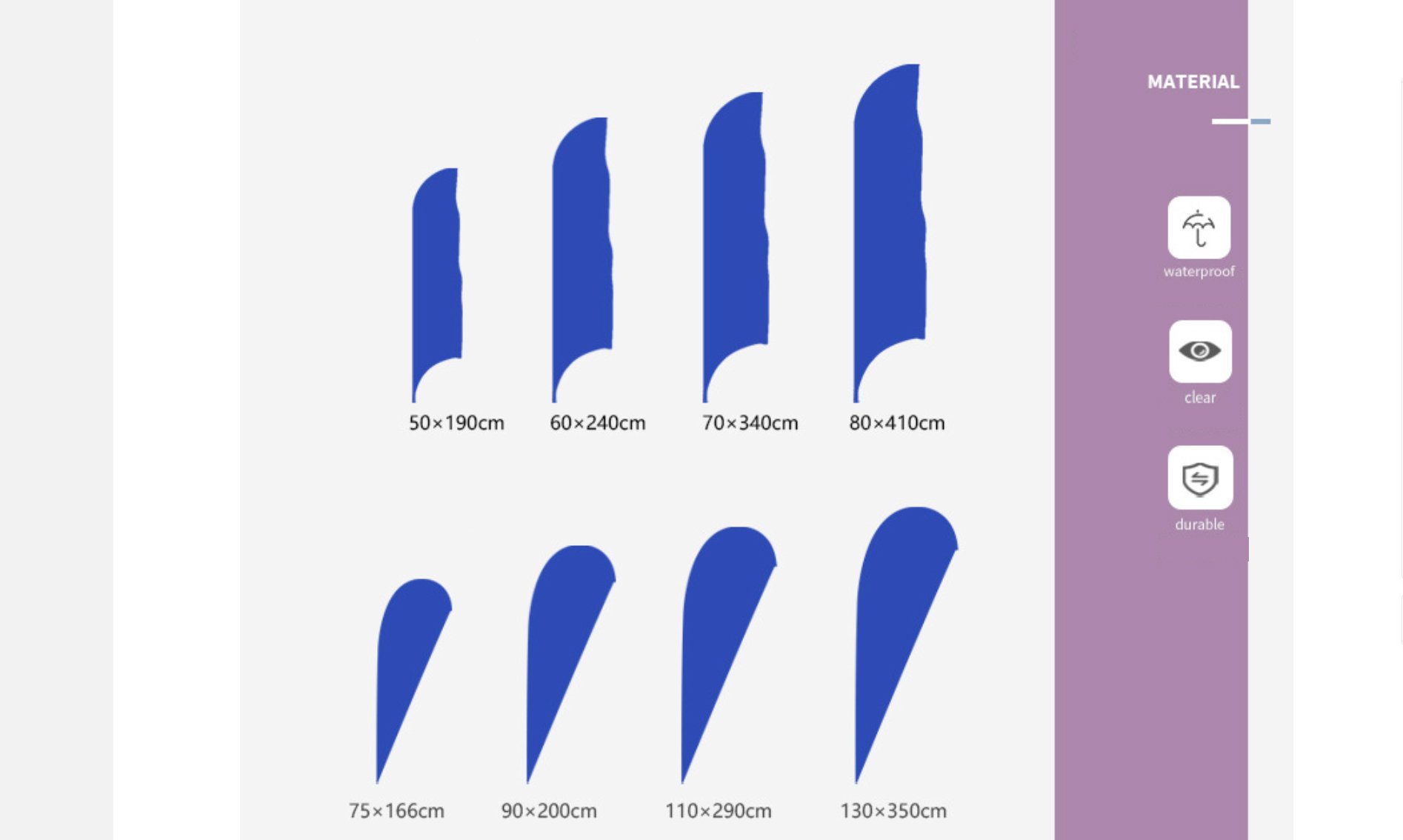

2. Size and Configuration

Consider the size and configuration of the truss stand that will best suit your needs. Truss stands are available in different lengths and shapes, such as square or triangular. Assess the space available and the specific requirements of your application before making a decision.

3. Portability

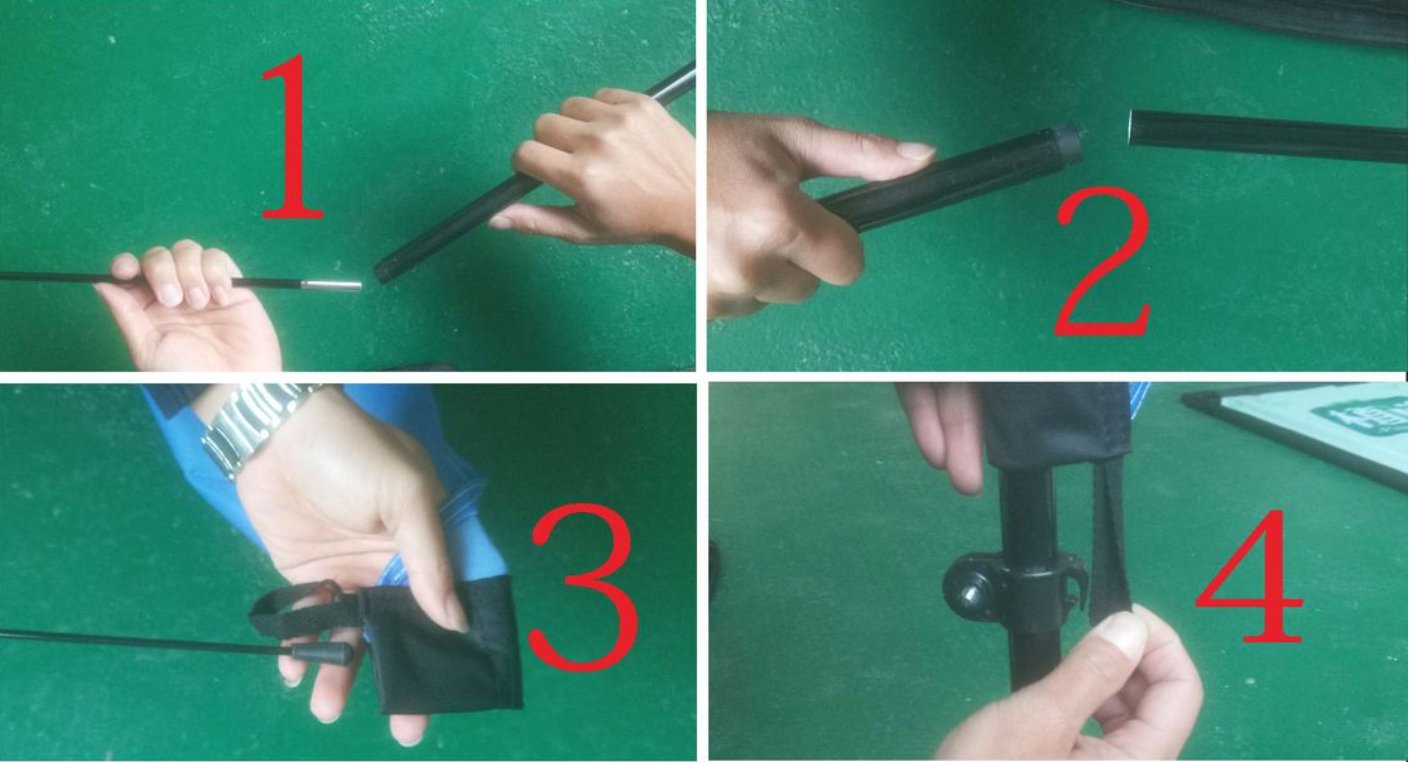

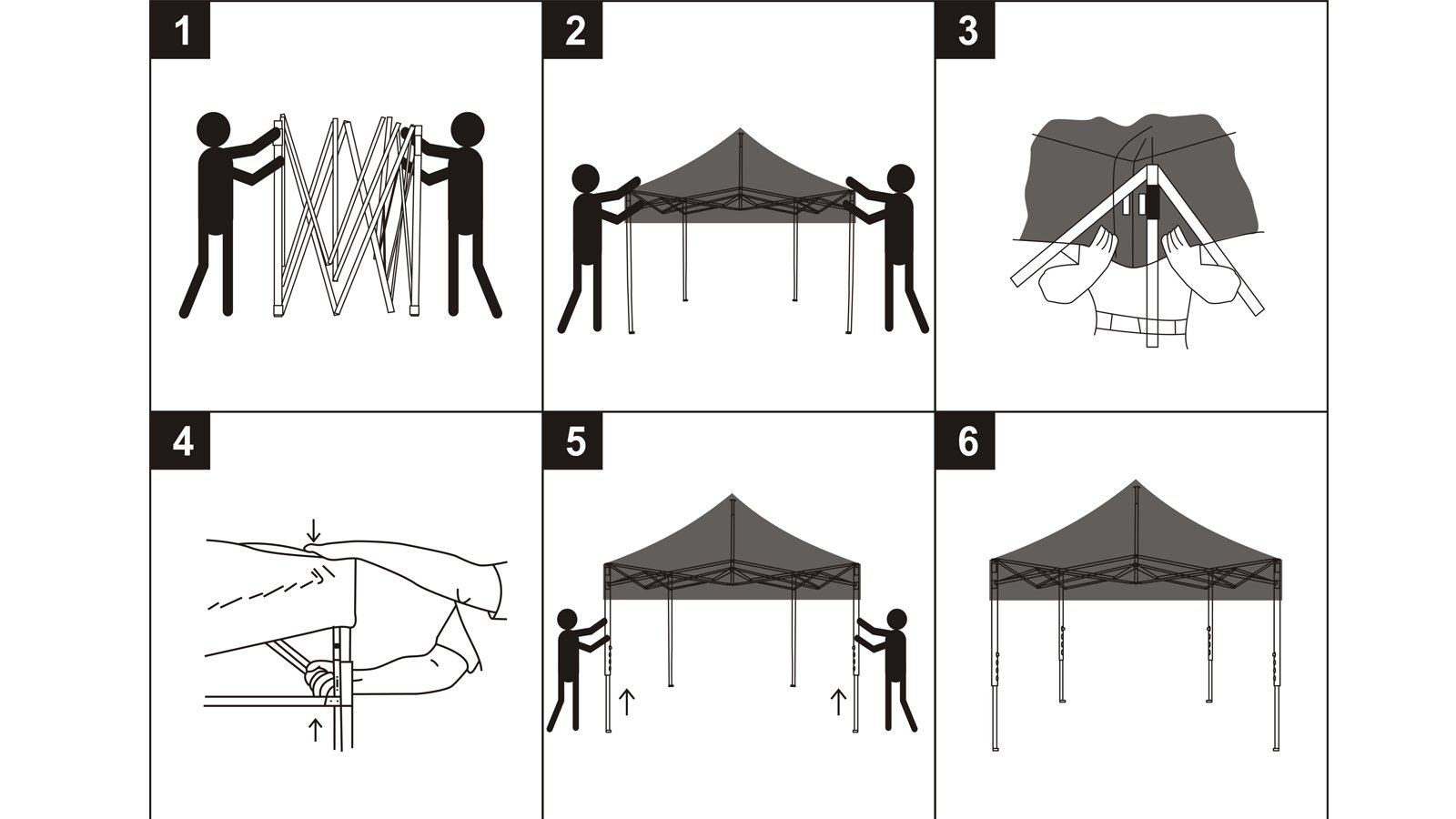

If you frequently travel or need to set up truss stands at different locations, portability is a crucial factor. Look for stands that are lightweight, easy to assemble, and come with convenient carrying cases.

Maintenance and Safety

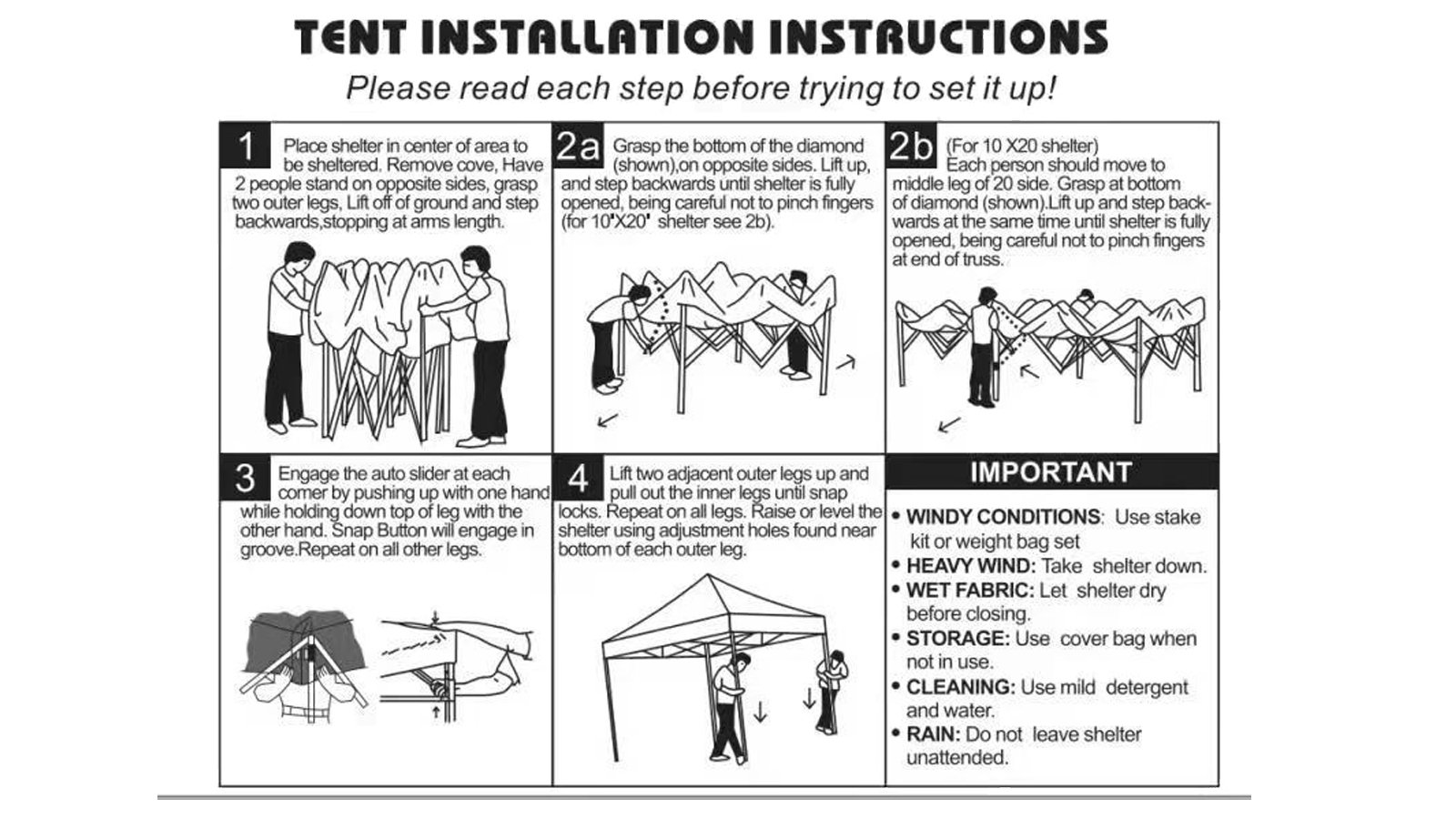

Proper maintenance and safety precautions are essential for ensuring the longevity and reliability of truss stands. Here are some tips:

1. Regular Inspections

Inspect your truss stands regularly for any signs of wear and tear. Check for loose connections, damaged parts, or any structural issues that may compromise their integrity. Promptly address any problems to prevent accidents or equipment damage.

2. Cleaning and Storage

Keep your truss stands clean by wiping them down with a soft cloth and mild detergent. Avoid using abrasive cleaners that can damage the finish. After use, store the truss stands in a dry and secure location to prevent rust and corrosion.

3. Proper Weight Distribution

Ensure that the weight on the truss stands is evenly distributed to prevent overloading and potential collapse. Follow the manufacturer's guidelines and seek professional advice if you are unsure about the weight distribution requirements.